Prior to development of any formulations

the physiochemical properties of drug molecule should be known to the

formulator. Preformulation studies have a significant part to play in

anticipating formulation problems and identifying logical path in liquid, semisolid

and solid dosage form technology.

Prior to the development of

pharmaceutical dosage forms, it is essential that be valid fundamental physical

and chemical properties of the drug molecule and other divided properties of

the drug powder are determined.

Preformulation

is to make available and realize information regarding:

1)

The degradation process

2)

Any adverse conditions relevant to the drug

3)

Bioavailability

4)

Pharmacokinetics and formulation of similar compounds

5)

Toxicity.

Preformulation

influences -

a)

Selection of the drug candidate itself

b)

Selection of formulation components

c)

API and drug product manufacturing processes

d)

Determination of the most appropriate container closure system

e)

Development of analytical methods

f)

Assignment of API retest periods

g)

The synthetic route of API

h)

Toxicological strategy

i)

To establish its compatibility with common excipients by observing caking,

liquefaction, colour change, odour formation.

It

also gives directions for the development of formulation in choice of drug

form, excipients, composition, and physical form.

Introduction of

· Preformulation

testing is the first step in the rational development of dosage forms of a drug

substance.

· It

can be defined as a phase of research & development process for an

investigation of physicaland chemical properties of new drug substance alone

or in combination with other excipients in order to development of stable, safe

and effective dosage form. The possible interactions with the various

components intended for use in the final drug product are also considered. It

is an effort that encompasses the study of such parameters as dissolution,

polymorphic forms and crystal size and shape, pH profile of stability, and drug

– excipient interactions, which may have a profound effect on a drug’s

physiological availability and physical and chemical stability.

Objectives of Preformulation

The

overall objective of preformulation testing is to generate information useful

to the formulator:

a.

To

formulate stable, safe and effective dosage form

b.

To

increased drug stability

c.

To

improve drug bioavailability

d.

Reduce

drug excipient incompatibility

e.

It

is important to have an understanding of the physical description of a drug

substance before dosage form development.

f.

It

is 1st step in rational development of a dosage form of a drug substance before

dosage form development.

Goals of

a.

To

establish the physico-chemical parameters of new drug substance.

b.

To

establish the physical characteristics

c.

To

establish the kinetic rate profile.

d.

To

establish the compatibility with the common excipient.

e.

To

choose the correct form of a drug substance.

Applications of

Preformulation

studies begins or shall be updated

·

Immediately

after the synthesis and initial toxicity screening of a new drug.

·

When

a newly synthesized drug shows pharmacological evidence that requires further

evaluation in man

·

When

formulation and dosage form changes are required

·

When

solid form changes of DS are required.

Before

beginning the formal preformulation programs the preformulation scientist must

consider the following factors:-

·

The

amount of drug available.

·

The

physicochemical properties of the drug already known.

·

Therapeutic

category and anticipated dose of compound.

·

The

nature of information, a formulation should have or would like to have.

Following

studies are conducted as basic preformulation studies; special studies are

conducted depending on the type of dosage form and the type of drug molecules -

·

Solubility

determination

·

pKa

determination

·

Partition

co-efficient

·

Crystal

properties and polymorphism

·

Practical

size, shape and surface area.

·

Chemical

stability profile.

Protocol

for Preformulation Studies

Outline

of principal areas of preformulation research

Preformulation

Parameters

|

Preformulation parameters

|

Method used

|

|

Organoleptic Properties

|

Colour and Odour Determination

|

|

Crystallinity & Polymorphyism

|

X-ray Diffraction Studies (Lachman,

1991)

|

|

Fine Particle Characterization

|

Microscopic Method (Lachman,

1991)

|

|

Solubility Profile

|

Equilibrium Solubility Method (I.P. 2007)

|

|

Solubilization

|

(Lachman, 1991)

|

|

Analytical Method Development

|

UV Spectroscopic Method, HPLC Method

|

|

Ionization Constant, pKa

|

Determination of Spectral Shifts by UV Spectroscopy

(Lachman, 1991)

|

|

Partition Coefficient

|

Using octanol / water,(Lachman, 1991)

|

|

Bulk Density

|

Tapping Method (Lachman, 1991)

|

|

Powder Flow Properties

|

% Compressibility Determination, Angle of Repose (Lachman,

1991)

|

|

Compatibility With Excipients

|

DSC (Stulzer and Rodriques et al., 2008)

|

|

Stability

|

Solution and Solid State Stability (PCT/US03/35012)

|

|

Stability Indicating Method Development

|

Forced Degradation Studies (Rao et al., 2009)

|

Organoleptic

properties

·

Colour: Stability problems, improve appearance

by including dye in body or coating

·

Taste: Palatability, flavours, and excipient

may be added.

·

Odour: Degradation products, e.g. Aspirin

stable form of drug to be used, flavours and excepients may be used.

Suggested

terminology to describe organoleptic properties of pharmaceutical powders

Colour Odour Taste

Off-White Pungent Acidic

Cream

Yellow Sulfurous Bitter

Tan Fruity Bland

Shiny Aromatic Intense

- Odourless Sweet

- - Tasteless

Purity

- Purity studies

are essential for further studies to be carried out safely.

- Impurities may

make a compound toxic or render it unstable.

- TLC, HPLC, GC

and Paper chromatography used.

- HPLC-Impurity

Index (II), Homogeneity index (HI).

- DTA, gravimetric

analysis and melting point by hot stage microscopy are other techniques.

- Impurity index (II):

Defined as the ratio of all responses (peak areas) due to components other than

the main one to the total area response.

- Homogeneity index

(HI): Defined as the ratio of response (peak area) due to main component to the

total response.

E.g.:

main component –retention time: 4.39min

-area

response: 4620

Impurities

– 7 minor peaks; area response: 251

- Total area response:

251+4620

Impurity

index: = 251/(4620+ 251)

= .0515

Homogeneity

index: = 1 - .0515

= .9485

Other

Tools in Assessment of Impurity

·

Differential

thermal analysis(DTA)

·

Thermogravimetric

analysis(TGA)

·

Differential

scanning calorimetry (DSC)

·

Powder

X-Ray Diffraction (PXRD)

Particle

size and shape

-

Various

chemical and physical properties of drug substances are affected by their

particle size distribution and shapes.

-

The

effect is not only on physical properties as well as biopharmaceutical

behavior.

-

It

also influence the flow and the mixing efficacy of powders and granules.

-

Fine

materials are relatively more open to attack from atmospheric oxygen, humidity,

than that of coarse material.

Particle

size determination

- Microscopy. E.g.

Light microscope, electron microscope.

- Anderson Pipette

- Sieving method

- Instruments

based on light blockage (HIAC) and blockage of electrical conductivity path (coulter

counter are available).

Common

techniques for measuring fine particles of various sizes

Technique Particle size

(mm)

Microscopic 1 - 100

Sieve > 50

Sedimentation > 1

Elutriation 1 - 50

Centrifugal < 50

Permeability > 1

Light

scattering 0.5 - 50

Shape

determination:

-

Microscopy

should be carried out to determine the ratio of longest to shortest dimension.

It is a shape factor.

Shape factor

Ø

Commonly

used shape factor converts volume of particle ‘v’ to its volumetric mean

diameter ‘av’

§

V=αv.av³

Ø

Shape

factor may be defined which converts the surface area ‘s’of a particle to its surface mean diameter ‘as’

§

S=αs.as²

Ø

Fractal

Dimensions are carried out by imaging techniques.

In

(N) = -n In(g)+q where: N= no. of

squares.

g=length of grid size.

n & q are

constants

Surface

area determination

-

It

is determined based on Brunaver Emitter Teller (BET) theory of adsorption.

-

Most

substances adsorb mono molecular layer of gas (Nitrogen) and temperature.

-

Air

adsorption and permeability methods

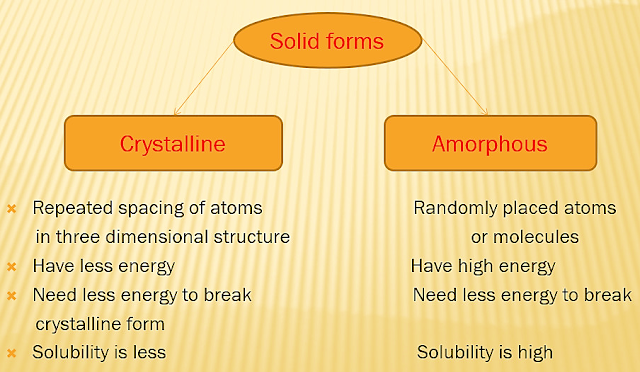

Crystallinity

and polymorphism

Crystal

habit and internal structure of a drug can affect bulk and physiochemical

properties

q HABBIT: Outer

appearance of crystal.

q Internal

structure

- Crystalline

- Amorpho

Characterization

of solid forms

Analytical

methods for characterization of solid forms

Method Material required per sample

a.

Microscopy 1mg

b.

Fusion

methods

1mg

(Hot stage microscopy)

c.

Infrared

spectroscopy 2-20mg

d.

X-ray

powder diffraction

500mg

e.

Scanning

electron microscopy 2mg

f.

Thermogravimetric

analysis 10mg

g.

Dissolution/Solubility

analysis mg to gm

Microscopy

q

All

substances are transparent examined under microscope – are either isotropic or

anisotropic

q

Isotropic

substances do not transmit the light – appears black – and have single

refractive index. E.g. Sodium Chloride

q

Anisotropic

substances – more than one refractive index – appear bright and brilliant color

– uniaxial and biaxial

q

Color

depends upon – thickness of crystal and diff. in refractive indices.

Thermal

Analysis

q Differential

Scanning Colorimetry (DSC) and Differential Thermal Analysis (DTH) measures the

heat loss or heat gain - resulting from physical or chemical changes.

q Two types of

processes

Endothermic: like fusion,

boiling, sublimation, vaporization, desolvation

Exothermic: like

crystallization, degradation

q Quantitative

measurement of these process have many application in preformulation study

including Purity, Polymorphism, solvation, degradation

X-Ray

Diffraction

·

Crystalline

materials gives characteristics pattern – by peaks in certain position &

varying intensities

·

Different

Polymorphs – different x-ray diffraction pattern due to crystal lattice.

·

Single

crystal x-ray analysis provides precise identification & description of a

crystalline substances.

Polymorphism

Substances can exist in more

than one crystalline form

·

Polymorphic

forms – diff. physical-chemical properties (incl. melting pt. & solubility)

·

Polymorphs:

-

Enatiotropic

-

Monotropic

·

Determination

method:

Thermodyanamically-van,

t Hoff plot (solubility vs temperature)

Directly

– by microscopic determination

Hygroscopicity

·

Many

substances, particularly water soluble salt form have a tendency to absorb

atmospheric pressure.

·

Change

in moisture level can influence chemical stability, flow ability, and compatibility.

·

It

can be monitored by Karl Fischer titration, TGA

Powder

Flow

·

The

pharmaceutical powders are classified as

-

Free

flowing

-

Cohesive

or non-free flowing

·

The

powder flow are affected by the changes in –

Density

Particle Size

Shape Free flowing

drug may become cohesive and

Electrostatic Charge necessitates an entirely new

formulation strategy

Adsorbed Moisture

Solubility

·

Solubility

> 1 % w/v

ð

no

dissolution-related absorption problem

·

Highly

insoluble drug administered in small doses may exhibit good absorption

·

Unstable

drug in highly acidic environment of stomach, high solubility and consequent

rapid dissolution could result in a decreased bioavailability.

·

The

solubility of every new drug must be determined as a function of pH over the

physiological pH range of 1 - 8.

Determination

of Solubility

Semi

quantitative determination:

Accurately

Quantitative determination:

General

Method of Increasing the Solubility

v

Addition

of co-solvent

v

pH

change method

v

Reduction

of particle size

v

Temperature

change method

v

Addition

of Surfactant

v

Complexation

Unique

Problems in Solubility Determination of Poorly Soluble Compounds

-

Solubility

could be over estimated due to the presence of soluble impurities

-

Saturation

solubility is not reached in a reasonable length of time unless the amount of

solid used is greatly in excess of that needed to saturation

-

Many

compounds in solution degrade, thus making an accurate determination of

solubility difficult

-

Difficulty

is also encountered in the determination of solubility of metastable forms that

transform to more stable forms when exposed to solvents

pH-Solubility

Profile

Poorly-soluble

weakly-acidic drugs:

pH = pKa + log

[(St - So)/So]

Poorly-soluble

weakly-basic drugs:

pH = pKa + log

[So/(St - So)]

where

So = solubility of unionized free acid or base

St = total solubility (unionized + ionized)

Process

of Solubilization

The

process of solubilization involves the breaking of inter-ionic or

intermolecular bonds in the solute, the separation of the molecules of the

solvent to provide space in the solvent for the solute, interaction between the

solvent and the solute molecule or ion.

Step

1:

Holes opens in the solvent

Step2: Molecules of

the solid breaks away from the bulk

Step

3:

The free solid molecule is intergraded into the hole in the solvent

Solubilization

can be enhanced by:

-

Use

more soluble metastable polymorph

-

Use

of complexation (eg.Ribloflavin-xanthinescomplex)

-

Use

of high-energy co-precipitates that are mixtures of solid solutions and solid

dispersions (eg. Griseofulvin in PEG 4000, 6000, and 20,000) in PEG 4000 and

20,000 -> supersaturated solutions in PEG 6000 -> bioavailability in

human twice > micronized drug

-

Use

of suitable surfactant

Partition

Coefficient

It

is the ratio of unionized drug distributed between organic and aqueous phase at

equilibrium.

P o/w = (C oil / C water) equilibrium

-

It

ratio of unionized drug in organic & aq. phase

-

It

measure lipophilicity

-

Major

role in drug transport

-

Analytical

separation

Ionization

Constant

·

The unionized species are more lipid-soluble

and hence more readily absorbed.

·

The GI absorption of weakly acidic or basic

drugs is related to the fraction of unionized drug in solution.

·

Factors affecting absorption:

-

pH

at the site of absorption

-

Ionization constant

-

Lipid

solubility of unionized species

“pH-partition

theory”

Henderson-Hasselbalch

equation

For

acids:

pH

= pKa + log [ionized

form]/[unionized form]

For

bases:

pH

= pKa + log [unionized

form]/[ionized form]

Determination

of Ionization Constant

1. Potentiometric pH-Titration

2. pH-Spectrophotometry Method

3. pH-Solubility Analysis

Dissolution

Diagram showing

dissolution and absorption of solid dosage form into blood circulation

PADDLE TYPE BASKET TYPE

2

types of systems to maintain uniform hydrodynamic conditions

1.

Static

disc dissolution apparatus

2.

Rotating

disc apparatus

Intrinsic

Dissolution

Film

Theory

The

dissolution of a solid in its own solution is adequately described by

Noyes-Nernst’s “Film Theory”.

-dW = DAK

(Cs - C)

dt h

Where

dW/dt = dissolution rate

A = surface

area of the dissolving solid

D = diffusion

coefficient

K = partition

coefficient

h = aqueous diffusion layer

Cs = solubility

of solute

C = solute concentration in the bulk medium

·

Intrinsic dissolution rate (mg/cm2/min) is

characteristics of each solid compound in a given solvent under fixed

hydrodynamic conditions

·

Intrinsic dissolution rate helps in

predicting if absorption would be dissolution rate-limited

·

1

mg/cm2/min --> not likely to present dissolution rate-limited

absorption problems

·

<

0.1 mg/cm2/min --> usually exhibit dissolution rate-limited

absorption

·

0.1

- 1.0 mg/cm2/min --> more information is needed before making any

prediction

Effect

of particle size of phenacetin on dissolution rate of the drug from granules

Solid

State Stability

·

For

identification of stable storage condition

·

Also

for identification of compatible excipient for a formulation

·

Extent

a product retains within specified limits and through its period of storage and

use

Stability

studies conducted in the preformulation phase:

·

Solid-state

of the drug alone

·

Solution

phase

·

With

the expected excipients

Photolytic

stability

·

Many

drugs fade or dropped on exposure light.

·

Exposure

of drug 400 and 900 foot-candles of illumination for 4 and 2 week periods

respectively is adequate to provide some idea of photosensitivity.

·

Resulting

data may be useful in determining if an amber colored container is required for

formulation.

Stability

to Oxidation

·

Drug’s

sensitivity to oxidation can be examined by exposing it to atmosphere of high

oxygen tension. Usually a 40% oxygen atmosphere allows for rapid evaluation.

·

Samples

are kept in desiccators equipped with three-way stop cocks, which are

alternatively evacuated and flooded with desired atmosphere.

·

The

process is repeated 3 or 4 times to ensure 100% desired atmosphere. Results may

be useful in predicting if an antioxidant is required in the formulation or if

the final product should be packaged under inert atmospheric conditions.

Solution

phase stability

·

As

compared with the dry form, the degradation is much rapid in solution form. It

is important ascertain that the drug doesn’t degrade when exposed to GI fluid.

·

The

pH based stability study, using different stimulator GI condition can be

designed.

·

A

poor solution stability of drug may urge the formulator to choose a less

soluble salt form, provided the bioavailability is not compromised.

Compatibility

studies

·

The

knowledge of drug excipients interaction is useful for the

formulation to select appropriate excipients.

·

The

described preformulation screening of drug excipients interaction requires only

5mg of drug in a 50% mixture with the excipients to maximize the likelihood of

obscuring an interaction.

·

Mixtures

should be examined under nitrogen to ultimate oxidation and paralytic effect at

a standard heating rate on DSC, over a temperature range, which will encompass

any thermal changes due to both the drug and appearance or disappearance one or

more peaks in themogrames of drug excipient mixtures are considered of

indication of interaction.

Flow

diagram to identify excipient compatibility with drug

Formulation

Recommendation

·

Upon

completion of preformulation evaluation of a new drug candidate, it recommended

that a comprehensive report be prepared highlighting problems associated with

this molecule

·

These

Reports re extremely important in preparing regulatory documents

Conclusion

q

Preformulation

studies have a significant part to play in anticipating formulation problems

and identifying logical path in both liquid and solid dosage form

technology.

q

By

comparing the physicochemical properties of each drug candidate with in a

therapeutic group, the preformulation scientist can assist:

-

the

synthetic chemist to identify the optimum molecule,

-

provide

the biologist with suitable vehicles to elicit pharmacological response and

-

advise

the bulk chemist about the selection and production of the best salt with

appropriate particle size and morphology for subsequent

processing.

Comments

Post a Comment